Навигация

Определение качественных характеристик зубчатого зацепления

7.4. Определение качественных характеристик зубчатого зацепления.

Определение коэффициента перекрытия:

![]()

![]()

Определение коэффициентов относительного скольжения.

где

![]()

Полученные результаты сводим в таблицу.

Таблица 7.1

| х | 0 | N1B | N1C | N1D | N1P | N1F | N1G | N1H | N1J | N1K | N1L | N1N2 |

|

| - | -4.18 | -1.38 | -0.447 | 0 | 0.37 | 0.58 | 0.72 | 0.82 | 0.895 | 0.953 | 1 |

|

| 1 | 0.809 | 0.584 | 0.315 | 0 | -0.573 | -1.36 | -1.254 | -4.507 | -8.44 | -20.84 | - |

8. Синтез кулачкового механизма.

8.1. Задачи синтеза кулачкового механизма.

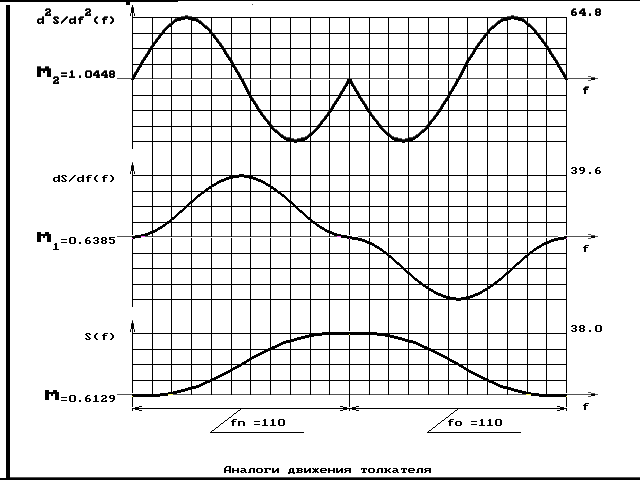

Аналоги движения тотлкателя.

1 S = 0.000 S1 = 0.000 S2 = 0.000 V = 0.000 A = 0.000 FI = 0

2 S = 0.031 S1 = 0.969 S2 = 20.017 V = 21.312 A = 440.381 FI = 6

3 S = 0.245 S1 = 3.780 S2 = 38.075 V = 83.163 A = 837.654 FI = 11

4 S = 0.807 S1 = 8.159 S2 = 52.406 V = 179.498 A = 1152.932 FI = 16

5 S = 1.848 S1 = 13.677 S2 = 61.607 V = 300.887 A = 1355.353 FI = 22

6 S = 3.452 S1 = 19.793 S2 = 64.777 V = 435.448 A = 1425.102 FI = 28

7 S = 5.648 S1 = 25.909 S2 = 61.607 V = 570.009 A = 1355.353 FI = 33

8 S = 8.407 S1 = 31.427 S2 = 52.406 V = 691.398 A = 1152.932 FI = 38

9 S = 11.645 S1 = 35.806 S2 = 38.075 V = 787.733 A = 837.654 FI = 44

10 S = 15.231 S1 = 38.617 S2 = 20.017 V = 849.584 A = 440.381 FI = 50

11 S = 19.000 S1 = 39.586 S2 = 0.000 V = 870.896 A = 0.000 FI = 55

12 S = 22.769 S1 = 38.617 S2 = -20.017 V = 849.584 A = -440.381 FI = 61

13 S = 26.355 S1 = 35.806 S2 = -38.075 V = 787.733 A = -837.654 FI = 66

14 S = 29.593 S1 = 31.427 S2 = -52.406 V = 691.398 A = -1152.932 FI = 72

15 S = 32.352 S1 = 25.909 S2 = -61.607 V = 570.009 A = -1355.353 FI = 77

16 S = 34.548 S1 = 19.793 S2 = -64.777 V = 435.448 A = -1425.102 FI = 83

17 S = 36.152 S1 = 13.677 S2 = -61.607 V = 300.887 A = -1355.353 FI = 88

18 S = 37.193 S1 = 8.159 S2 = -52.406 V = 179.498 A = -1152.932 FI = 94

19 S = 37.755 S1 = 3.780 S2 = -38.075 V = 83.163 A = -837.654 FI = 99

20 S = 37.969 S1 = 0.969 S2 = -20.017 V = 21.312 A = -440.381 FI = 105

21 S = 38.000 S1 = 0.000 S2 = 0.000 V = 0.000 A = 0.000 FI = 110

22 S = 38.000 S1 = 0.000 S2 = 0.000 V = 0.000 A = 0.000 FI = 110

23 S = 38.000 S1 = 0.000 S2 = 0.000 V = 0.000 A = 0.000 FI = 110

24 S = 38.000 S1 = -0.000 S2 = 0.000 V = -0.000 A = 0.000 FI = 110

25 S = 37.969 S1 = -0.969 S2 = -20.017 V = -21.312 A = -440.381 FI = 116

26 S = 37.755 S1 = -3.780 S2 = -38.075 V = -83.163 A = -837.654 FI = 121

27 S = 37.193 S1 = -8.159 S2 = -52.406 V = -179.498 A = -1152.932 FI = 126

28 S = 36.152 S1 = -13.677 S2 = -61.607 V = -300.887 A = -1355.353 FI = 132

29 S = 34.548 S1 = -19.793 S2 = -64.777 V = -435.448 A = -1425.102 FI = 138

30 S = 32.352 S1 = -25.909 S2 = -61.607 V = -570.009 A = -1355.353 FI = 143

31 S = 29.593 S1 = -31.427 S2 = -52.406 V = -691.398 A = -1152.932 FI = 149

32 S = 26.355 S1 = -35.806 S2 = -38.075 V = -787.733 A = -837.654 FI = 154

33 S = 22.769 S1 = -38.617 S2 = -20.017 V = -849.584 A = -440.381 FI = 159

34 S = 19.000 S1 = -39.586 S2 = 0.000 V = -870.896 A = 0.000 FI = 165

35 S = 15.231 S1 = -38.617 S2 = 20.017 V = -849.584 A = 440.381 FI = 170

36 S = 11.645 S1 = -35.806 S2 = 38.075 V = -787.733 A = 837.654 FI = 176

37 S = 8.407 S1 = -31.427 S2 = 52.406 V = -691.398 A = 1152.932 FI = 182

38 S = 5.648 S1 = -25.909 S2 = 61.607 V = -570.009 A = 1355.353 FI = 187

39 S = 3.452 S1 = -19.793 S2 = 64.777 V = -435.448 A = 1425.102 FI = 192

40 S = 1.848 S1 = -13.677 S2 = 61.607 V = -300.887 A = 1355.353 FI = 198

41 S = 0.807 S1 = -8.159 S2 = 52.406 V = -179.498 A = 1152.932 FI = 203

42 S = 0.245 S1 = -3.780 S2 = 38.075 V = -83.163 A = 837.654 FI = 209

43 S = 0.031 S1 = -0.969 S2 = 20.017 V = -21.312 A = 440.381 FI = 215

44 S = 0.000 S1 = -0.000 S2 = 0.000 V = -0.000 A = 0.000 FI = 220

45 S = 0.000 S1 = -0.000 S2 = 0.000 V = -0.000 A = 0.000 FI = 220

46 S = 0.000 S1 = 0.000 S2 = 0.000 V = 0.000 A = 0.000 FI = 360

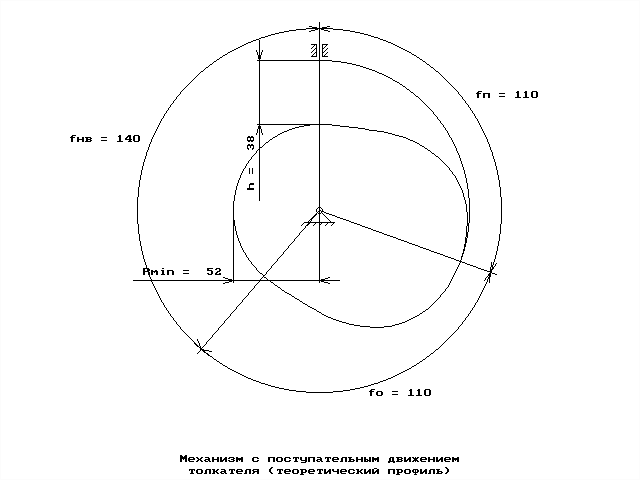

F1 = 110 F2 = 0 F3 = 110

H = 38.000

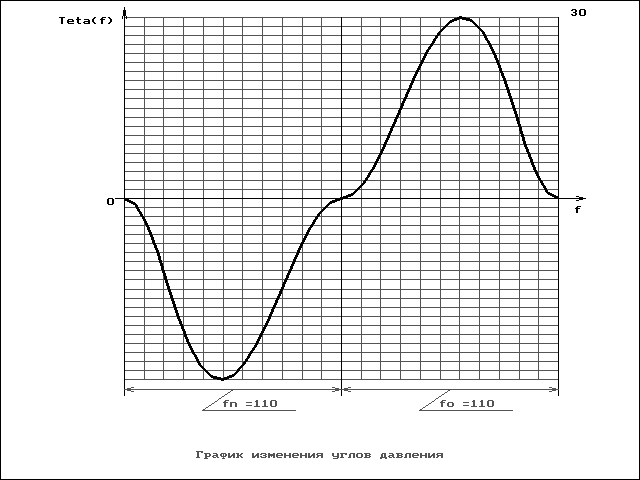

E = 0 Rmin = 52.000 TETAM = 30.000

R[1] = 52.000 B[1] = 0.000 TETA[1] = -0.0

R[2] = 52.031 B[2] = 5.500 TETA[2] = -1.1

R[3] = 52.245 B[3] = 11.000 TETA[3] = -4.1

R[4] = 52.807 B[4] = 16.500 TETA[4] = -8.8

R[5] = 53.848 B[5] = 22.000 TETA[5] = -14.3

R[6] = 55.452 B[6] = 27.500 TETA[6] = -19.6

R[7] = 57.648 B[7] = 33.000 TETA[7] = -24.2

R[8] = 60.407 B[8] = 38.500 TETA[8] = -27.5

R[9] = 63.645 B[9] = 44.000 TETA[9] = -29.4

R[10] = 67.231 B[10] = 49.500 TETA[10] = -29.9

R[11] = 71.000 B[11] = 55.000 TETA[11] = -29.1

R[12] = 74.769 B[12] = 60.500 TETA[12] = -27.3

R[13] = 78.355 B[13] = 66.000 TETA[13] = -24.6

R[14] = 81.593 B[14] = 71.500 TETA[14] = -21.1

R[15] = 84.352 B[15] = 77.000 TETA[15] = -17.1

R[16] = 86.548 B[16] = 82.500 TETA[16] = -12.9

R[17] = 88.152 B[17] = 88.000 TETA[17] = -8.8

R[18] = 89.193 B[18] = 93.500 TETA[18] = -5.2

R[19] = 89.755 B[19] = 99.000 TETA[19] = -2.4

R[20] = 89.969 B[20] = 104.500 TETA[20] = -0.6

R[21] = 90.000 B[21] = 110.000 TETA[21] = -0.0

R[22] = 90.000 B[22] = 110.000 TETA[22] = -0.0

R[23] = 90.000 B[23] = 110.000 TETA[23] = 0.0

R[24] = 90.000 B[24] = 110.000 TETA[24] = 0.0

R[25] = 89.969 B[25] = 115.500 TETA[25] = 0.6

R[26] = 89.755 B[26] = 121.000 TETA[26] = 2.4

R[27] = 89.193 B[27] = 126.500 TETA[27] = 5.2

R[28] = 88.152 B[28] = 132.000 TETA[28] = 8.8

R[29] = 86.548 B[29] = 137.500 TETA[29] = 12.9

R[30] = 84.352 B[30] = 143.000 TETA[30] = 17.1

R[31] = 81.593 B[31] = 148.500 TETA[31] = 21.1

R[32] = 78.355 B[32] = 154.000 TETA[32] = 24.6

R[33] = 74.769 B[33] = 159.500 TETA[33] = 27.3

R[34] = 71.000 B[34] = 165.000 TETA[34] = 29.1

R[35] = 67.231 B[35] = 170.500 TETA[35] = 29.9

R[36] = 63.645 B[36] = 176.000 TETA[36] = 29.4

R[37] = 60.407 B[37] = 181.500 TETA[37] = 27.5

R[38] = 57.648 B[38] = 187.000 TETA[38] = 24.2

R[39] = 55.452 B[39] = 192.500 TETA[39] = 19.6

R[40] = 53.848 B[40] = 198.000 TETA[40] = 14.3

R[41] = 52.807 B[41] = 203.500 TETA[41] = 8.8

R[42] = 52.245 B[42] = 209.000 TETA[42] = 4.1

R[43] = 52.031 B[43] = 214.500 TETA[43] = 1.1

R[44] = 52.000 B[44] = 220.000 TETA[44] = 0.0

R[45] = 52.000 B[45] = 220.000 TETA[45] = 0.0

R[46] = 52.000 B[46] = 360.000 TETA[46] = 0.0

6. Силовое исследование рычажного механизма.

6.1 Задачи силового исследования.

При силовом исследовании решаются следующие задачи

Определение сил действующих на звенья механизма.

Определение реакций в кинематических парах.

Определение уравновешивающего момента или силы действующей на ведущее звено.

0 комментариев